Chende Technology awarded provincial-level green factory, achieving Longgang's zero breakthrough!

Sep 22, 2025

Recently, the Zhejiang Provincial Department of Economy and Information Technology announced the list of provincial-level green and low-carbon industrial parks and factories for 2025. Chengde Technology Co., Ltd.—a vice president unit of the China Packaging Federation and standing vice president unit of the Longgang Printing and Packaging Industry Association—was successfully recognized as a provincial-level green factory, making it the first in Longgang City!

.webp)

01 R&D Innovation

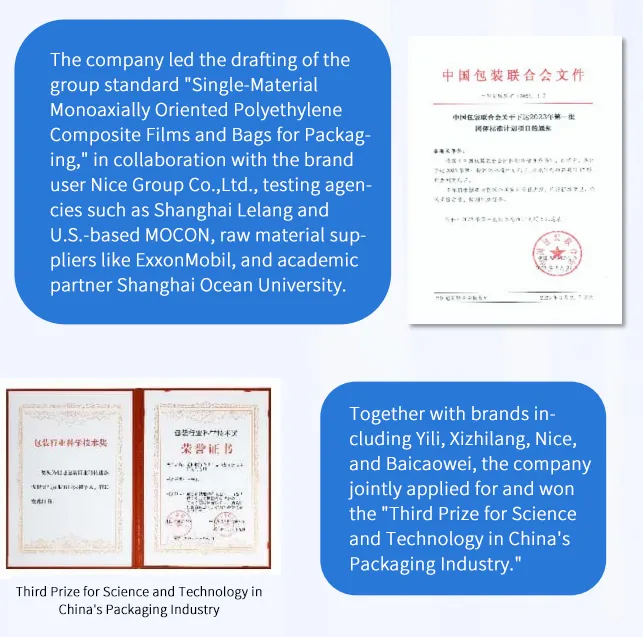

Chengde Technology led the drafting of two group standards, including the "Single-Material Uniaxially Oriented Polyethylene Composite Film and Bag for Packaging." These standards were developed in collaboration with brand partners such as Nice, testing institutions including Shanghai Lelang and MOCON (USA), raw material supplier ExxonMobil, and academic institutions like Shanghai Ocean University. Additionally, Chengde Technology jointly applied with leading brands such as Yili, Strong, Nice, and Be&Cheery and was awarded the "Third Prize of Science and Technology in China's Packaging Industry.

02 Energy Resource Input, Environmental Protection Measures, and Management

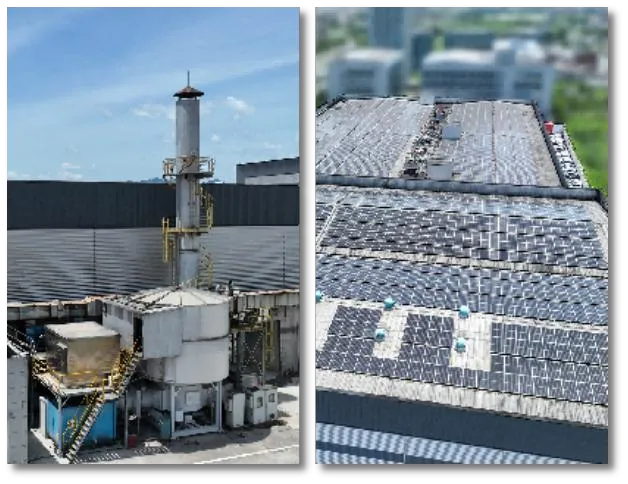

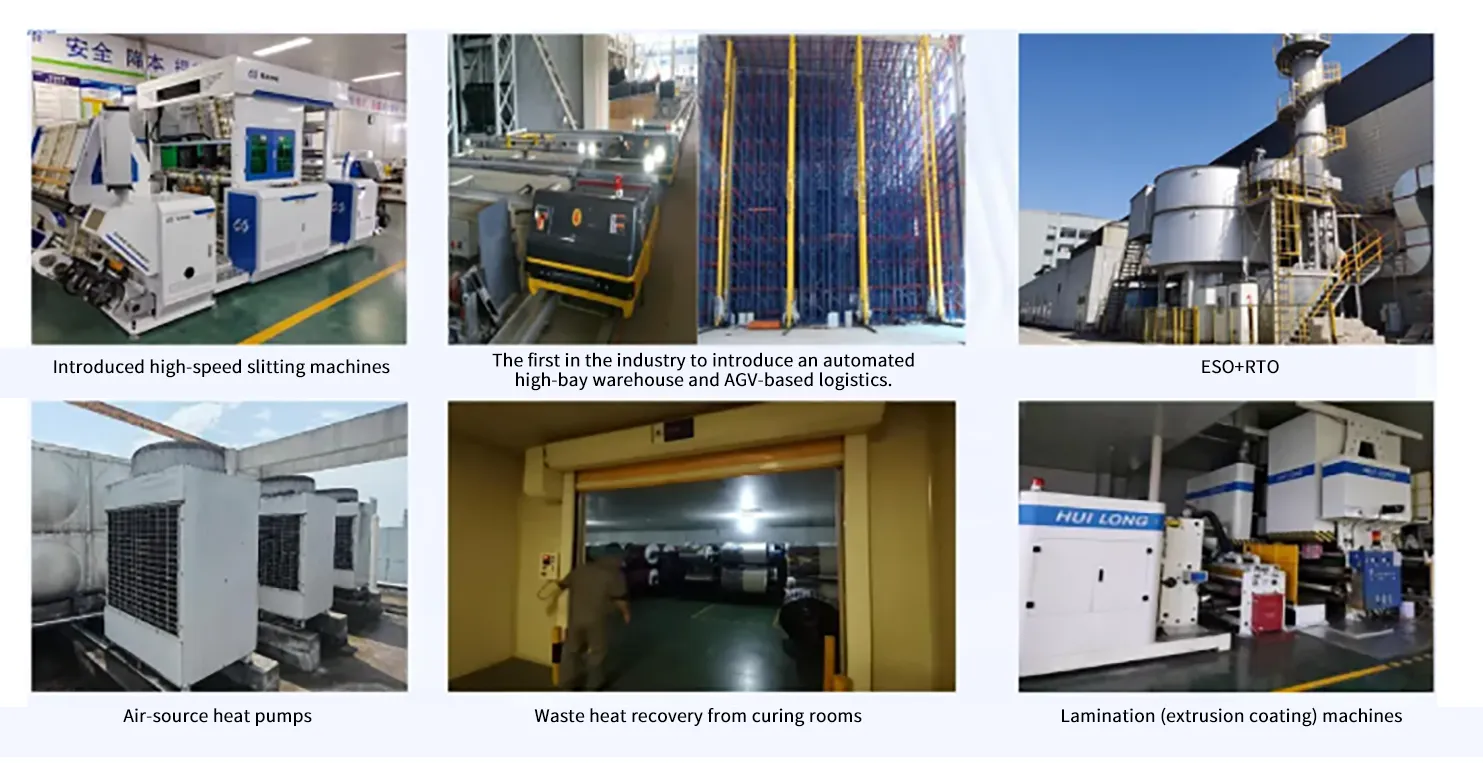

In recent years, Chengde Technology has implemented multiple energy-saving, carbon-reduction, and water-conservation upgrades. These include the construction of a 1,980 kWp distributed photovoltaic power station (with a total power generation of 2.46 million kWh in 2024), the introduction of new slitting machines, regenerative thermal oxidation (RTO) technology for treating mainstream organic waste gases, and automated storage systems. Additional improvements encompass composite process upgrades, optimization of slitting and winding processes, enhancements in product debugging procedures, improvements in surface winding, waste heat recovery and utilization, adoption of air-source heat pumps, development of single-material solutions, and the use of eco-friendly packaging materials.

Pollutant treatment equipment primarily includes waste gas and wastewater treatment facilities. Organic waste gases generated during printing, laminating, and curing (drying) processes are treated through an ESO + RTO waste gas treatment system to ensure compliant emissions. Domestic wastewater is pre-treated using oil separators and septic tanks within the facility before being discharged to the Longgang Town Wastewater Treatment Plant for centralized treatment and final discharge. Both wastewater and waste gas treatment capacities meet design requirements, with actual emission data exceeding higher-tier standards and outperforming industry averages.

03 Green Production

Since 2019, Chengde Technology has initiated projects and R&D on mono-material materials and packaging. In 2020, the company introduced a mono-material polyethylene stretch film production line and an HP Indigo 20000 digital press, achieving zero VOCs emissions and adopting the world’s latest digital printing technology.

In 2021, Chengde won the Meishi Cup China Packaging Innovation and Sustainable Development Award for its "MDO High-Barrier Mono-Recyclable Eco-Friendly Packaging." By 2022, the company officially launched mono-material polyethylene stretch composite film and bag solutions.

In 2023, Chengde collaborated with a well-known brand to successfully develop "Polyolefin Eco-Friendly Packaging." In 2024, in partnership with brands such as Yili, Strong, Nice, and Be&Cheery, the company was awarded the Third Prize in the China Packaging Industry Science and Technology Award.

Next, Chengde Technology will focus on product lightweighting. Over the next three years, by optimizing product design, the thickness of plastic composite film bags will be reduced by 10%, which is expected to decrease raw material usage by approximately 100 tons annually while maintaining the same physical properties and functionality of the products.

Equipment upgrades will be carried out by conducting energy efficiency assessments of existing production and general equipment to identify those requiring improvements. Over the next three years, equipment will be gradually upgraded and replaced to enhance energy utilization efficiency by 10%–15%.

Energy structure optimization will involve increasing the proportion of renewable energy in total energy consumption to reduce reliance on traditional fossil fuels. The scale of distributed photovoltaic power stations will be expanded to 2,500 kWp, while the introduction of other renewable energy sources, such as biomass, will be explored to ensure renewable energy accounts for over 15% of total energy consumption.

Process improvements will further optimize production techniques to reduce energy consumption and pollutant emissions during manufacturing. This will achieve a 10% reduction in comprehensive energy consumption per unit product and a 10% decrease in carbon emissions per unit product.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Oct 09, 2025

Q3 Review & Q4 Quality Mobilization Conference

Oct 09, 2025

CPiS 2025: Green Momentum, Smart Future

.webp?x-oss-process=image/resize,w_100/quality,q_100)